Specification

- The Mastic will be prepared with Cookers or Coldruns either mechanically agitated or manually.

- The mastic composition is on Bitumen , Stone Dust, Stone grit & lime stone powder.

- The burner of the cooker is fired & LSP in required quantity is heated along with SD &SG in machine .while bitumen is heated for melting separately in heating drums.

- Once lime is hot ,SD is added and then Bitumen is mixed followed by SG, mix well and then the mastic is ready

- Joints are cut in L shape

- Provide anti-skid treatment as per specification (If required)

- Open the masticated area once the normal room temperature is achieved

- Typical composition of mix desighn will be as under

- A)Base mastic –The ratio will be a)Lime Stone Powder:-300kgs b)Sone Dust:- 460kgs c)Bitumen (15.55-16.02%) ie. 140-145 kgs As Per MORTh 4, Table500.32

- B)Mastic: To added stone grit, ie. 600 kgs the total batch size will be aprox. 1500kgs.The the hardness number as per MOST will be 10-20 Bitumen will be as per 500.29

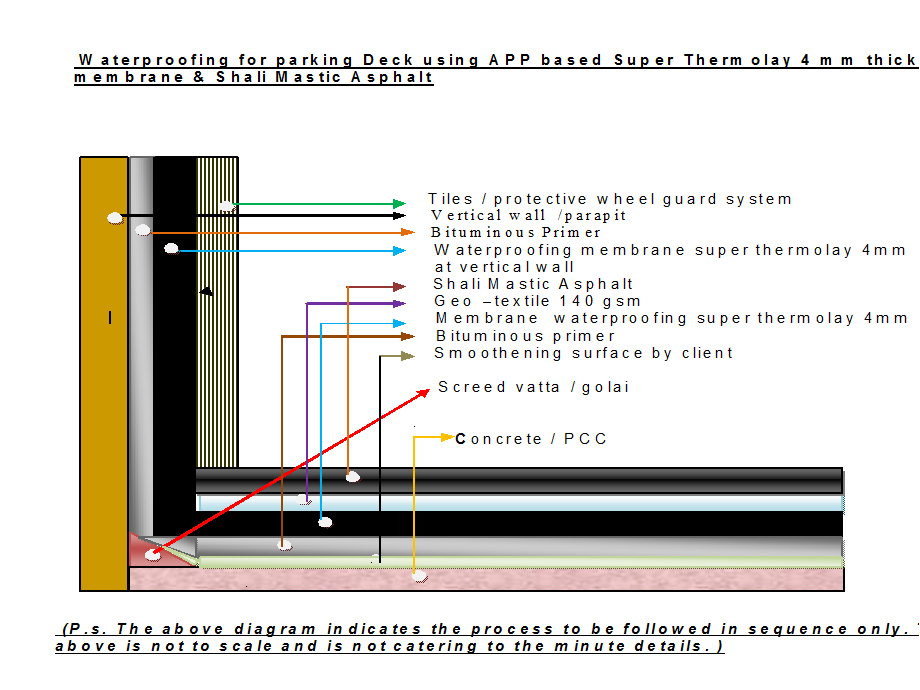

Parking Deck waterproofing

Waterproofing for parking Deck using APP based Super Thermolay 4 mm thick membrane & Shali Mastic Asphalt